Video: De Reuringdienst – Brightlands Circular Space – Resolved Technologies SUBS EN

Interview with Jean-Jacques Collin, CCO of ReSolved Rechnoligies.

Interview with Jean-Jacques Collin, CCO of ReSolved Rechnoligies.

Afgedankt plastic van hoge kwaliteit belandt vaak in de verbrandingsoven of op de vuilstort. Recyclen om er nieuwe grondstof van te maken, is lastig en soms zelfs onmogelijk. Als het wel gebeurt, is het resultaat vaak onder de maat. De Geleense start-up ReSolved Technologies heeft er iets op gevonden. „We lossen het op. Letterlijk.”

Plastic uit elektrische apparaten, computers, auto’s, chipszakken of douchekoppen wordt momenteel mondjesmaat gerecycled tot nieuwe, schone grondstoffen. Start-up Resolved Technologies heeft daar letterlijk een oplossing voor gevonden: oplossen in een oplosmiddel. Volgend jaar moet een eerste pilotfabriek op chemiecomplex Chemelot via deze methode 25 kilo plastic per uur gaan recyclen.

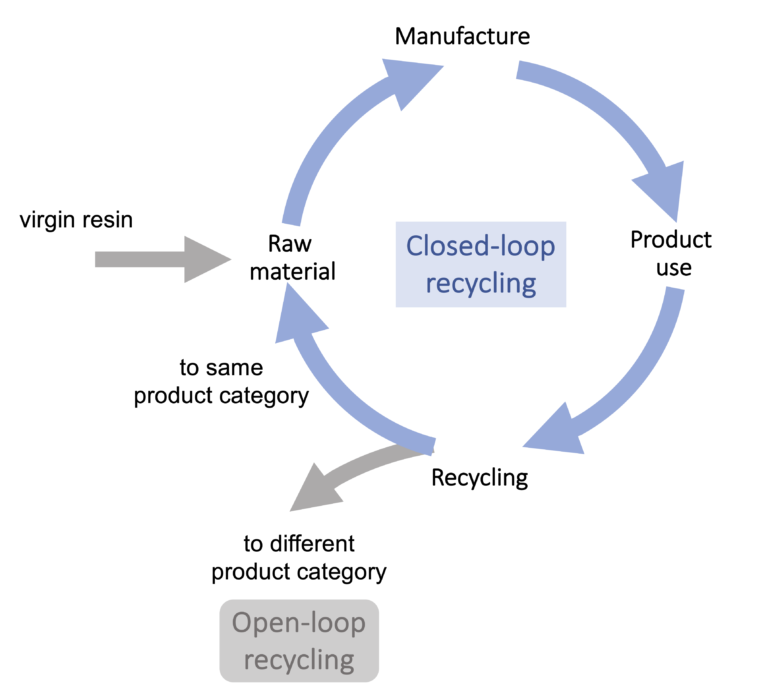

Voor technische kunststoffen, of engineering plastics, wordt closed loop recycling steeds belangrijker. Maar vaak bevatten deze materialen ongewenste componenten, waardoor hoogwaardig hergebruik wordt belemmerd. ReSolved Technologies ziet de oplossing in het letterlijk oplossen van de afvalstromen. ‘Wij denken dat de markt er nu klaar voor is.’

Advanced solvent-based technology for the closed-loop recycling of engineering plastics Norbert FraunholczReSolved Technologies BVUrmonderbaan 226167 RD Sittard-GeleenNetherlandsM: +31-(0)6-247 074 83E: norbert@resolved-tech.comURL: www.resolved-tech.com Engineering plastics (e.g., ABS, PC and PMMA) have superior mechanical properties, such asstrength and gloss. Therefore, they are…

SUSTAINABILITY – Solvent-based recycling, alongside mechanical recycling, should take on a larger role, according to entrepreneur Norbert Fraunholcz. He explains in this article what this entails.

The Netherlands – Recycling high-quality engineering plastics requires a specific approach. According to Norbert Fraunholcz of startup Resolved Technologies, dissolving is the best option for most plastic types in this group of materials. During Dragons’ Den of Transition, the startup is looking for chain partners. And Fraunholcz immediately thinks a little bigger. He is also looking for partners to introduce the ‘dual carbon and circularity credit’.

Plastics are one of the largest group of raw materials. In fact, plastics production by volume outweighs the production of all metals combined. The circularity of raw materials has been in the spotlights in recent years, as it is one of the main pillars of sustainability together with greenhouse gas emissions.

Recycling from waste is the most important tool to make raw materials circular. At the same time, the CO2 emission associated with the production of plastics can be reduced by 50 to 80% through recycling compared to production from fossil fuels. Given the fact that approx. half of the global CO2 emission is related to the production of raw materials, these savings are significant.