Closed-loop recycling is a key factor for making engineering plastics circular

Engineering plastics have superior mechanical properties, such as strength and gloss. Examples are ABS, PC, PA and PMMA. Engineering plastics are primarily used in high-end products, such as electrical and electronic (E&E) devices and vehicles.

When it comes to end-of-life solutions, closed-loop recycling is the only sustainable option for this group of plastics. This is mainly due to a lack of alternative applications to absorb lower-grade recycled material in quantity. In turn, this implies very high quality requirements on the recycled material to replace virgin resins in these high-end products.

Current recycling solutions are insufficient to turn engineering plastic waste to high-grade recycled material in quantity. As a result, the recycled content of plastic parts in E&E devices and automobiles is currently less than 2%. On the other hand, the EU target for plastics in general is 24% to be achieved by 2030.

Recycling of engineering plastics is challenging

The majority of engineering plastic waste arisings originate from complex post-consumer waste streams like E-waste and car scrap. In addition, a significant portion of these plastics contains legacy additives, the use of which is banned by EU law.

Therefore, recycling requires the individual plastic types be sorted and the legacy additives be removed as a minimum. These conditions make recycling using existing technologies very challenging.

The EU has the most advanced waste collection and recycling infrastructure for E-waste and car scrap worldwide. Nevertheless, approx. 95% of the engineering plastics contained in these waste streams is currently downcycled, incinerated or landfilled in the EU.

Solvent-based recycling – the missing link

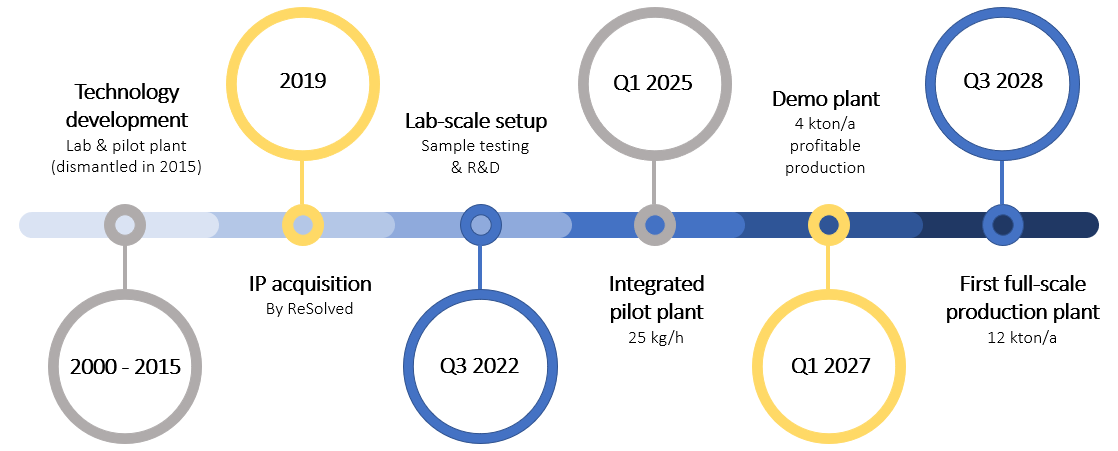

Roadmap

FAQ

In solvent-based recycling (also often referred to as solvent-based purification), the target plastic is entirely dissolved in a solvent. Subsequently, the obtained solution is purified to remove different kinds contaminants. Finally, the purified polymer is recovered by removing solvent.

A characteristic feature of all chemical recycling techniques is that the polymer chain of the plastic material is broken down to smaller molecules, e.g., to monomers, naphtha or syngas, that are rebuilt again to the original polymeric material through polymerization.

In solvent-based recycling, however, the plastic material undergoes physical changes only and the polymer chains remain intact throughout the whole process. Therefore, solvent-based recycling belongs – together with mechanical recycling – to the group of physical recycling methods.

1. The contaminants are removed from a homogeneous liquid, i.e. the solution containing the dissolved plastic material, which is much more effective than separation of these contaminants from solid particles, i.e. flakes, such as in mechanical recycling. Therefore, the quality of plastic waste recycled through the solvent-based method is in general far superior to mechanically recycled material.

2. While mechanical recycling is suited to remove exterior contaminants only, solvent-based recycling allows the removal of interior contaminants or components as well, such as fillers, colorants, flame retardants and softeners.

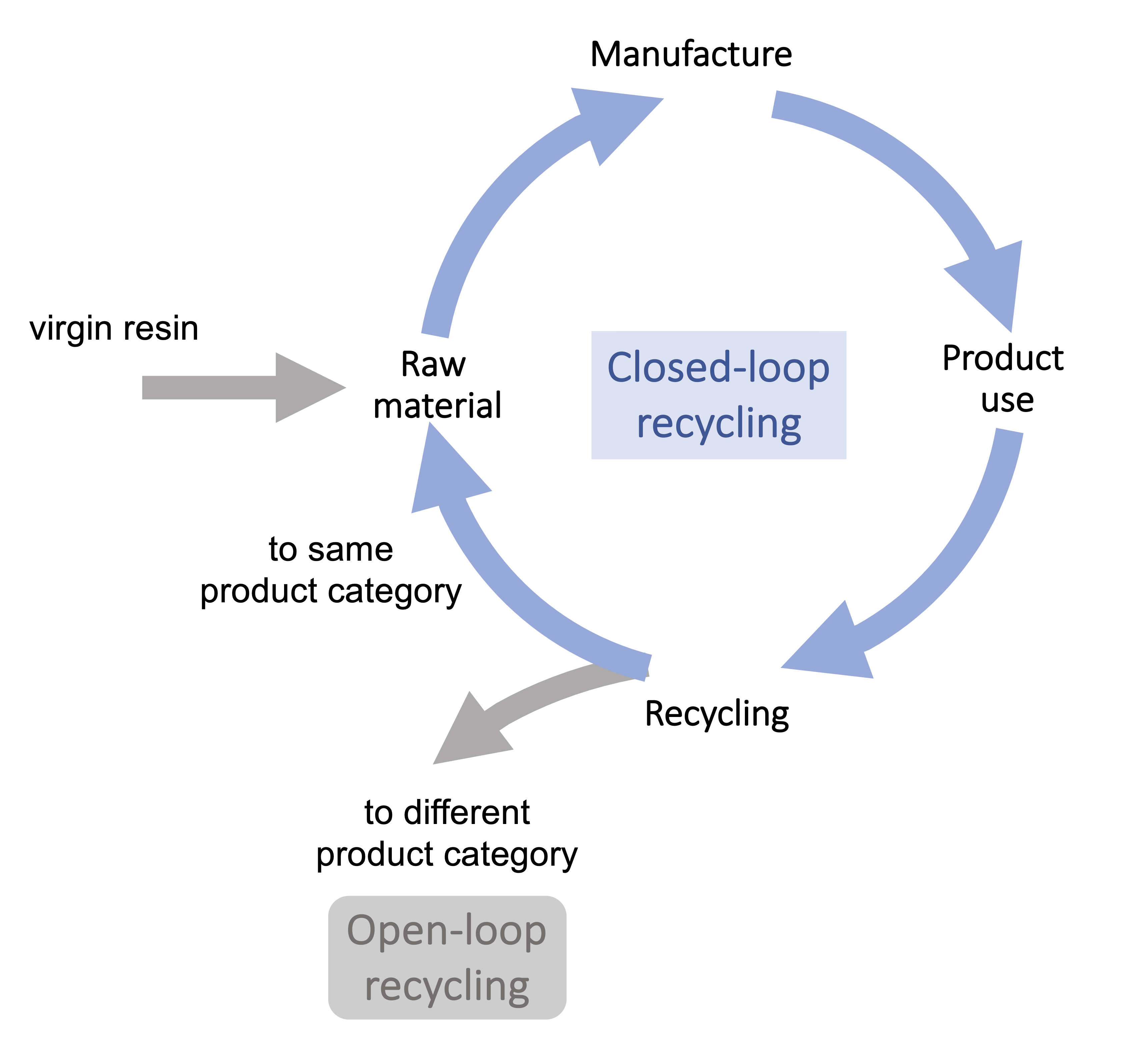

In closed-loop recycling, the material of a given end-of-life product is recycled and used to produce the same type of product. An example is recycled ABS originating from obsolete vacuum cleaners that is used to produce casings for new vacuum cleaners.

In practice, E-scrap is a mix of different kind of electrical and electronic devices, so that the recycled plastic derived from this waste stream usually cannot be originated back to a given type of device. Therefore, it makes sense to broaden the definition of closed-loop recycling to allow the application of the recycled material in the same category of products, i.e. E-waste to E-devices.

Our Partners