Products & Services

Products

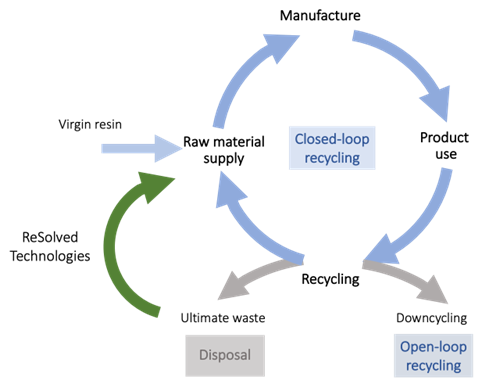

Interested in closed loop recycling? – Consider our ReSolved technology

Our hybrid solvent-based technology is capable of producing recycled engineering plastics of near-virgin quality from complex post-consumer waste streams, such as E-waste and car scrap. These high-quality recycled materials can be used in closed-loop applications for a broad range of products.

The Resolved technology is favorable from the viewpoints of profitability, carbon footprint, compatibility to existing recycling infrastructure, quality match with market demand and fit into EU policies.

We invite companies in the plastic supply chain to join our ReSolved project, i.e. OEM’s, virgin plastic producers and waste feedstock owners/suppliers.

Supplying recycled engineering plastics of near-virgin quality

We are excited to announce that we are setting up a high-tech recycling facility based on a unique hybrid solvent-based technology for ABS and HIPS scrap. The plant will be equipped with modules to remove additives, such as colorants, from post-consumer E-waste and car scrap.

We will supply recycled ABS and HIPS of near-virgin quality for closed-loop applications in, e.g., electrical devices and in the automotive sector. We expect our first production line to become operational in 2027. In the meantime, we are constructing a pilot plant for sample testing and demonstration. The pilot plant will be available in early 2025.

Carbon & Circularity Credits

Recycling has a double benefit.

Plastics are one of the largest group of raw materials. In fact, plastics production by volume outweighs the production of all metals combined. The circularity of raw materials has been in the spotlights in recent years, as it is one of the main pillars of sustainability together with greenhouse gas emissions.

Recycling from waste is the most important tool to make raw materials circular. At the same time, the CO2 emission associated with the production of plastics can be reduced by 50 to 80% through recycling compared to production from fossil fuels. Given the fact that approx. half of the global CO2 emission is related to the production of raw materials, these savings are significant.

The use of low-emission recycled plastic in new products increases the sustainability performance of the whole product value chain. Furter, the interdependency between the stakeholders in the value chain is much stronger in a circular economy than in a linear one. Yet, contributing to the transition is not always easy for companies that are not directly involved in recycling, such as brand owners and manufacturers.

Reduce carbon footprint and increase circularity.

Carbon credits are a useful tool to help companies in reducing their carbon footprint in the most economical way. Unfortunately, no comparable credit system exists for the circularity of plastics or for other raw materials. Introducing such circularity credits might be useful on its own. On the other hand, recycling has a double benefit as outlined above: it contributes to the circularity of products and reduces CO2 and other greenhouse gas emissions. Therefore, it makes sense to combine these gains into dual Carbon & Circularity (C&C) credits.

But there is more to C&C credits than simply combining two benefits into a single product. Regular carbon credits are generally used to offset CO2 emissions of an economic activity with carbon credits generated in another field of business. Mainly for this reason, this system is often criticized that it does not stimulate the reduction of CO2 emissions sufficiently. On the other hand, C&C credits will be issued and used in the same value chain and will therefore have a direct positive impact on improving the sustainability of the plastic value chain as a whole.

The net CO2 saving and the increase in circularity are easy to show when ultimate plasticwaste, i.e. waste that is currently landfilled or incinerated, is recycled in closed loop.

We ask: €300k to develop a market-ready C&C product.

We offer: C&C credits for 1.000 tons of CO2 equivalent for every €50k of contribution to our project.

Development of C&C credits

Buying C&C credits is an easy way to get involved and it helps companies in the most relevant way to increase the sustainability of their products on multiple levels. In that sense, C&C credits are more relevant to these parties than regular carbon credits, which are usually derived from biomass or other CO2 capture projects.

At ReSolved Technologies, we are developing this concept and will issue such C&C credits for recycled engineering plastics and PVC. The best way to ensure that the net CO2 savings and the increase in circularity are clear and verifiable, we will start to issue C&C credits derived from the recycling of ultimate plastic waste – i.e. waste that is currently landfilled or incinerated – in closed loop, see figure below. However, C&C credits can also be developed for projects that require some more complex calculations and verification of the net savings and gains.

The C&C concept will only work when there are enough issuers and buyers of such credits. Therefore, we invite companies and organizations that are interested in this concept to work with us to develop the C&C concept to a useful product that remains relevant for a long time.

Note: providing funds for the project is not a prerequisite for participation in the project. Click here to download our full C&C article.

Services

Finding the optimal process solution for your plastic waste

ReSolved Technologies offers technical consulting services to define next-level recycling solutions for your engineering plastic and soft PVC waste.

Our work starts with a thorough analysis of your plastic waste samples followed by developing a tailored process solution mainly based on mechanical and solvent-based techniques. Subsequently, the defined process solution can be tested on a lab and/or pilot scale depending on the availability of suitable equipment. Finally, we provide an evaluation of the economics of the proposed process.